In a groundbreaking development, the Czech Republic has witnessed the application of 3D printing technology using concrete for the construction of an ordinary apartment building. This remarkable feat was achieved within a mere two hours, as a robotic printer created an entire room right at the construction site of the Modřanský cukrovar project.

Over the past few years, 3D printing technology has made its mark in various industries, revolutionizing manufacturing processes in automotive, healthcare, and food sectors. However, the construction industry has been slower to adopt this innovation. Although there have been a few instances of 3D printing implementation in the Czech Republic, such as a small public transport stop in Prague, it has not been used directly on the construction site. The main challenge lies in the size of the products produced, leading to the current approach of printing building parts off-site and then transporting and installing them.

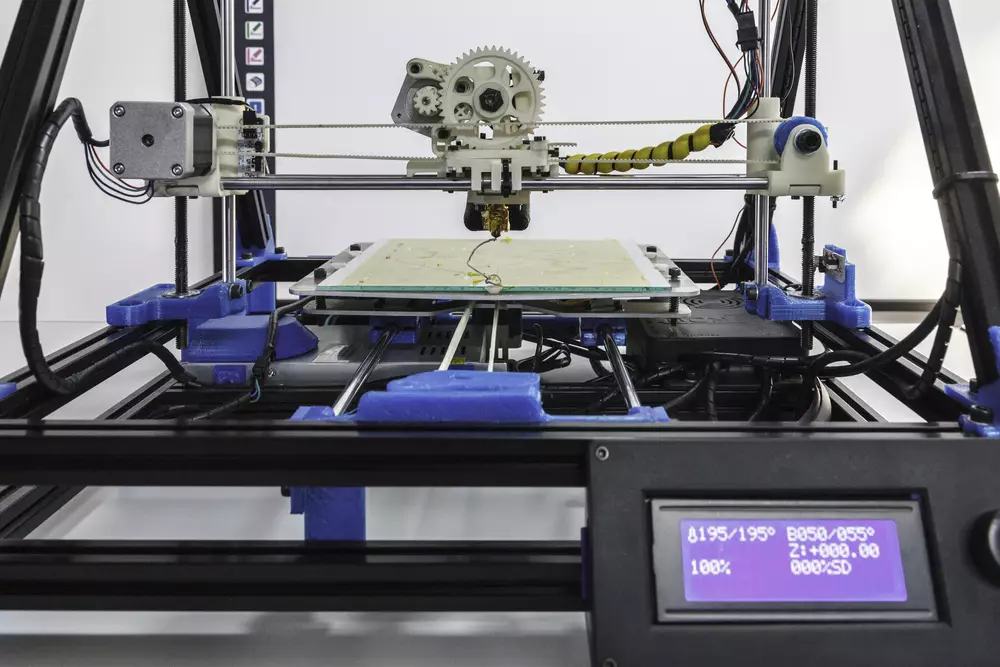

Nonetheless, a joint effort by Skanska and ICE Industrial Services has taken 3D “production” to the next level by introducing it at the construction site of the Modřanský cukrovar residential area. A robotic 3D printer was temporarily installed on the fourth floor of the ongoing building construction, where it efficiently printed an unconventional sanitary room using concrete within a short span of two hours. The printing material was sourced from local raw materials and demonstrated impressive strength, reaching a class of C30/37 or even higher.

Jiri Vambera from ICE Industrial Services emphasized their globally unique system for 3D printing concrete, allowing the use of commonly available local materials. The latest technology utilized in this project enabled printing speeds of up to 600 millimeters per second. This advancement is expected to significantly reduce costs compared to traditional construction methods, as stated by Vambera. Petr Michálek, head of Skanska Residential, added that the successful implementation of 3D printing in this technologically demanding type of construction could pave the way for a transformative impact on future residential projects.

Beyond accelerating the construction process and enhancing overall efficiency, 3D printing also contributes to more sustainable construction practices. The technology allows for the use of eco-friendly and recyclable materials, thereby minimizing negative environmental effects. Additionally, it aligns with the principles of the circular economy, as it can process recycled construction waste like plastics, bricks, concrete, mortar, and plaster, among others. Furthermore, the adoption of this revolutionary technology addresses labor shortages and provides an opportunity for the digitalization of the construction industry.